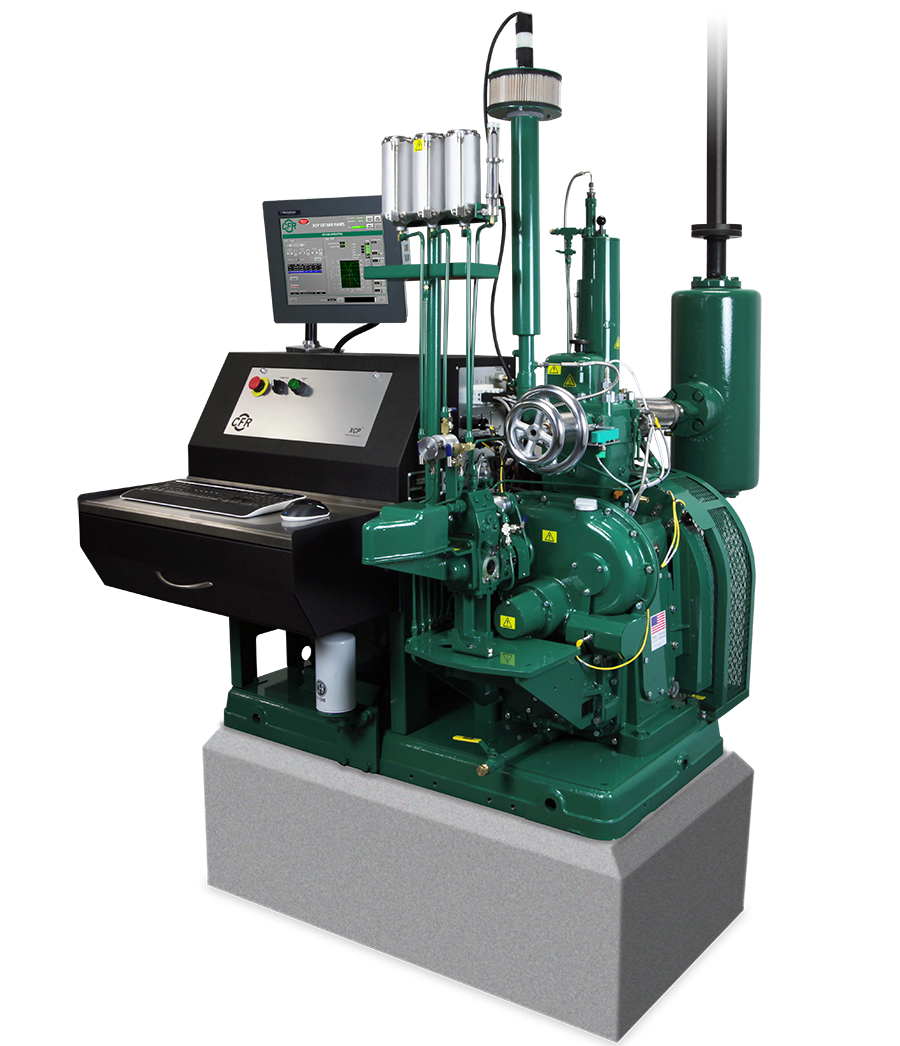

In the world of diesel fuel testing, the CFR® F5 Cetane Rating Unit has been a game-changer since its debut in 1938. It has revolutionized the assessment and certification of diesel fuels’ ignition quality, leaving a lasting impact on the automotive and petroleum sectors while maintaining the integrity of the fuel supply chain from refinery to pump.

Setting the Gold Standard in Fuel Testing

The CFR F5 Cetane Rating Unit is meticulously designed to meet and exceed global standards such as ASTM D613, IP 41, and EN ISO 5165. This commitment to excellence ensures that diesel fuels consistently reach peak quality.

Seamless Integration for Testing Confidence

A complete CFR Engines Inc. cetane fuel testing system includes the F5 engine unit, XCP™ Technology, and a CFR® exhaust surge tank. These components seamlessly unite to control critical parameters and ensure a flawless cetane test. Users can trust in a system that enhances efficiency and reliability, whether opting for a complete unit, an upgrade/conversion kit, or genuine CFR service parts.

Data Prowess with XCP Technology

The XCP Digital Control Panel automates data collection and presentation, ensuring accuracy by integrating with a Laboratory Information Management System (LIMS) while providing vital information such as handwheel positions, fuel flow rates, and environmental data.

Reliability Woven into Design

With a legacy dating back to 1929, CFR Engines Inc. products boast reliability built on upgrades and enhancements to withstand modern fuel testing environments with minimal maintenance.

Precision Unleashed Through Modern Instrument Control

The CFR F5 paired with XCP Technology leverages digital instrumentation for higher precision and accuracy through recording critical system data.

Cost-Efficiency Through One System Flexibility

The CFR F5 not only revolutionizes precision but also offers unparalleled flexibility and cost savings. With push-button control and guided testing prompts, users experience more efficient resource utilization, quicker tests, and reduced operator training.

Additional Highlights: Elevating Safety and Convenience

XCP integrated safety monitoring systems safeguard against various factors while user-friendly technology reduces operator training. On-screen indicators inform when “Injection Advance” and “Ignition Delay” stability are achieved, while an electronic maintenance log records vital maintenance information for future reference.

Experience Tomorrow’s Diesel Fuel Testing Today. Step into the future of diesel fuel testing with the CFR F5 Cetane Rating for superior results and peace of mind.

Frequently Asked Questions (FAQs) About the CFR® F5 Cetane Rating Unit

What is the importance of the CFR F5 Cetane Rating Unit?

The CFR F5 is crucial for determining and certifying the ignition quality of diesel fuels in automotive and petroleum industries.

How long has the CFR F5 been in use?

Since its introduction in 1938, it has proven itself reliable over eight decades.

Which standards does it comply with?

The CFR F5 complies with globally recognized standards including ASTM D613, IP 41, and EN ISO 5165.

What components are included in a complete system?

A complete system comprises the F5 engine unit, XCP™ Technology, and a CFR® exhaust surge tank.

How does XCP Technology improve data integrity?

It automates data capture/presentation reducing manual errors.

Is it user-friendly?

Yes! It’s designed for ease of use requiring minimal training.

How does it ensure reliability & longevity?

Through well-designed system upgrades/enhancements ensuring durability with minimal maintenance.

Are there additional safety features integrated?

Yes! It includes integrated safety monitoring systems protecting against various factors.

Does it offer on-screen indicators for monitoring stability?

Yes! The system includes on-screen indicators improving operator consistency.

Can it handle different types of diesel fuels including biodiesel blends?

Absolutely! It’s designed to assess a wide range of diesel fuels including biodiesel blends.

How does it contribute to environmental sustainability?

It incorporates environmentally friendly resistance temperature detectors prioritizing eco-conscious design elements.

Can it be remotely monitored/controlled?

Yes! With advanced remote monitoring capabilities enhancing operational convenience/flexibility.

What sets it apart in terms of user interface compared to others?

Its easy-to-use touch-screen Human-Machine Interface (HMI) panel minimizes learning curves ensuring efficient use/proficiency.

Does it provide support for industry-specific reporting requirements?

Absolutely! The XCP Technology seamlessly integrates into Laboratory Information Management Systems (LIMS), exceeding industry-specific reporting standards