Valencia, known for its vibrant economy and diverse industries, is a hub for the production of rubber parts. These parts, ranging from tires to tiny seals, play a crucial role in various sectors including automotive, aerospace, and manufacturing.

This article explores the fascinating world of Rubber parts in Valencia, discussing their uses, manufacturing processes, and the challenges and innovations in the industry.

Understanding Rubber Parts

Rubber is a flexible and durable material that can be shaped into a wide variety of products. In Valencia, rubber parts are used in everything from cars and planes to everyday household items. The most common rubber parts include:

- Tires: Used in vehicles to provide traction and absorb shocks.

- Seals and Gaskets: Ensure tight sealing to prevent leaks in everything from water pipes to engines.

- Hoses and Belts: Used in machinery and vehicles to transfer fluids and power.

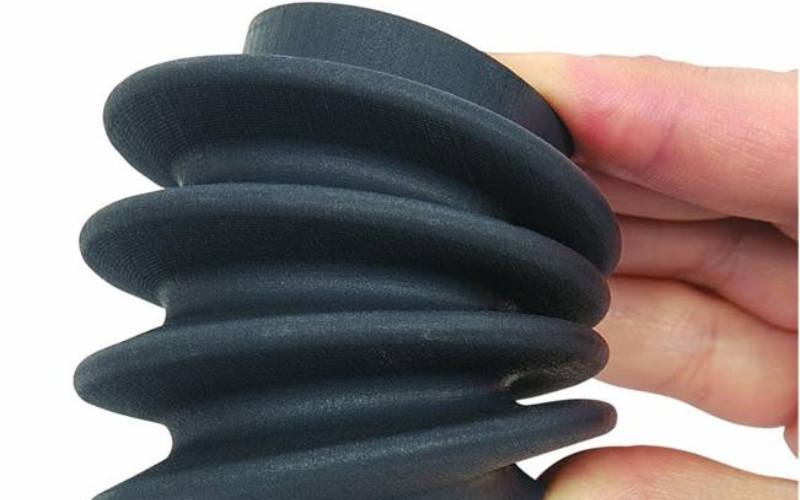

- Vibration Dampers: Absorb and reduce vibrations in machines and structures.

These parts are essential for the functionality and safety of many products and systems.

The Manufacturing of Rubber Parts

The process of manufacturing Rubber Parts In Valencia involves several steps, which can vary depending on the type of part being made. Generally, the process includes:

- Material Selection

Choosing the right type of rubber, whether natural or synthetic, based on the part’s required properties like flexibility, heat resistance, or durability.

- Compounding

Mixing the raw rubber with other ingredients such as fillers, plasticizers, and vulcanizing agents to enhance its properties.

- Molding

Shaping the rubber mixture into the desired form using methods like injection molding, compression molding, or extrusion.

- Curing

Applying heat and pressure to the molded rubber to set its shape and properties permanently.

- Finishing

Trimming, polishing, and finishing the rubber part to ensure it meets quality standards.

Each of these steps requires precise control to ensure that the final product performs as expected.

Uses of Rubber Parts in Valencia

In Valencia, rubber parts are utilized across many industries:

- Automotive Industry

Rubber parts like tires, seals, and hoses are integral to the design and function of automobiles. Valencia’s automotive sector relies heavily on high-quality rubber parts to build vehicles that are safe and efficient.

- Aerospace Industry

Rubber seals and gaskets are used in aircraft to withstand extreme pressures and temperatures, ensuring the safety and efficiency of air travel.

- Manufacturing and Construction

Rubber vibration dampers and mounts are used in machinery and construction to reduce noise and extend the life of equipment.

- Healthcare

Rubber is also used in the production of medical devices and equipment, such as gloves, tubing, and gaskets, which require high standards of hygiene and flexibility.

Challenges Facing the Rubber Industry in Valencia

While the rubber industry is vital to Valencia’s economy, it faces several challenges:

- Environmental Concerns

Rubber production, especially synthetic rubber, involves chemicals that can be harmful to the environment. There is increasing pressure to find more sustainable and less polluting manufacturing methods.

- Competition from Other Materials

With advancements in materials science, rubber parts are increasingly competing with parts made from plastics and composites, which can be cheaper or offer different properties.

- Economic Fluctuations

Changes in the global economy can affect the demand for rubber parts, impacting the stability of the industry in Valencia.

Innovations in Rubber Manufacturing

To overcome these challenges, companies in Valencia are investing in innovative technologies and methods:

- Green Manufacturing

Development of eco-friendly rubber compounds and recycling methods to reduce the environmental impact of rubber production.

- Automation and Robotics

Using automated systems and robots to improve the efficiency and quality of rubber part production.

- Advanced Material Science

Research into new forms of rubber and hybrid materials that offer improved performance and sustainability.

Conclusion

The rubber parts in Valencia industry plays a critical role in supporting various sectors through the supply of essential . From tires that move vehicles to seals that protect machines, rubber parts are integral to the functionality and efficiency of many products. Despite facing significant challenges, the industry continues to evolve and adapt through innovation. As Valencia moves forward, the rubber parts industry is set to remain a key player in its economic landscape, driving advancements in technology and sustainability. Thank visiting myblogpost.com.au